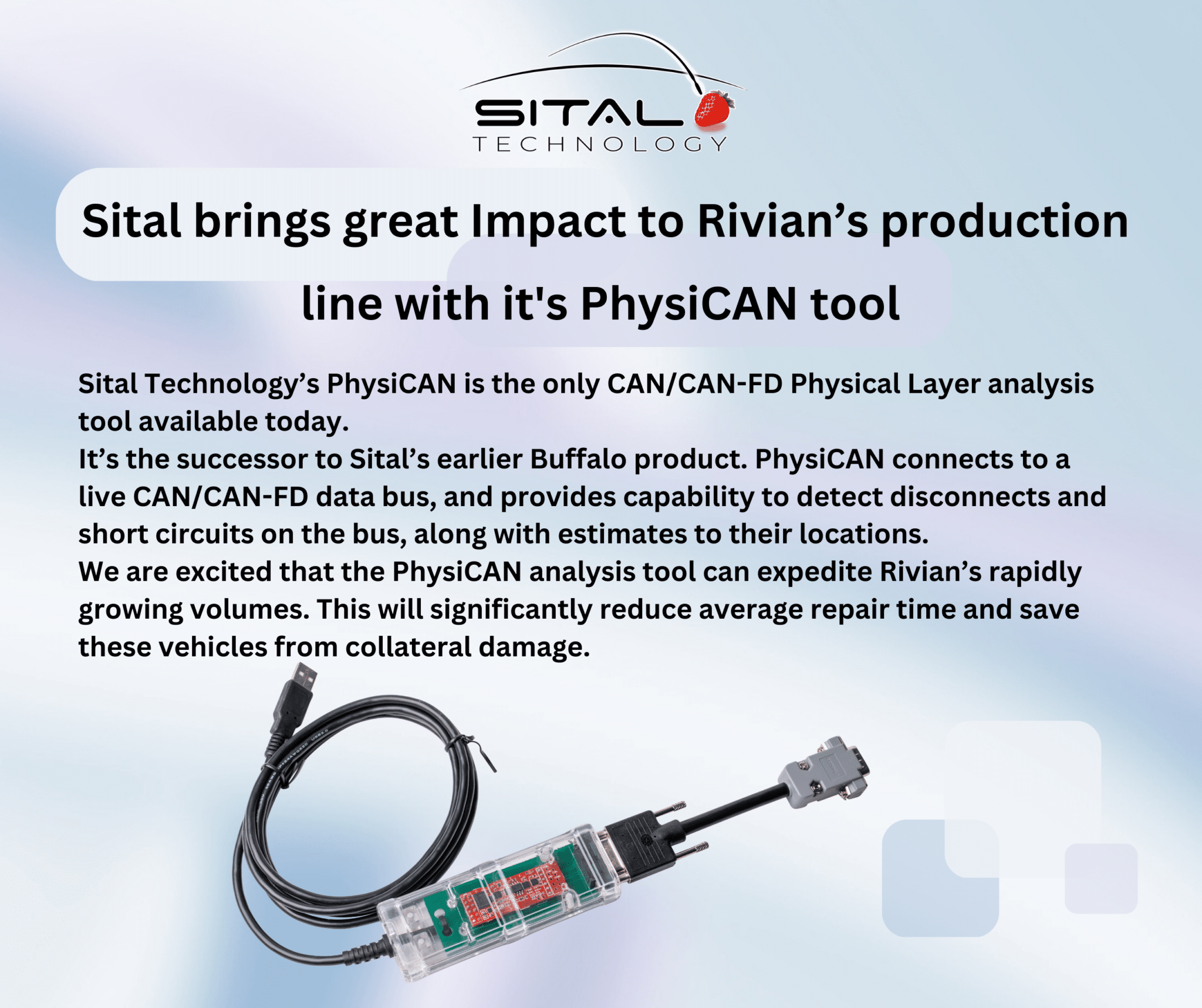

Sital Technology’s PhysiCAN is the only CAN/CAN-FD Physical Layer analysis tool available today.

It’s the successor to Sital’s earlier Buffalo product. PhysiCAN connects to a live CAN/CAN-FD data bus, and provides capability to detect disconnects and short circuits on the bus, along with estimates to their locations.

Based on Buffalo statistics collected from 20 OEM assembly plants in North America, CAN bus wiring faults occur in about 1% of the vehicles with 3 CAN buses, and as many as 5% in complex vehicles with 15 to 20 buses.

These involve with estimated average repair times of 6 hours. During troubleshooting, collateral damage cost incurred is estimated to be 10-fold. A technician using PhysiCAN is able repair such faults in an average of 20 minutes with minimal collateral damage.

“We are excited that the PhysiCAN analysis tool can expedite Rivian’s rapidly growing volumes. This will save these vehicles from collateral damage. We enjoy each time we get a fault report and hear comments such as ‘…seriously it took me 1 minute to find…’, followed by a picture of a bent pin” said Ofer Hofman, founder and CTO of Sital Technology.

In addition according to Hofman, “Sital looks forward to expanding the use of PhysiCAN into service, and later introducing the embedded version into the vehicles themselves to enable preventive maintenance”.

For more details and information – click here.

For real-time updates, check out our LinkedIn page!